Tube bending calculations download#

Where can you find the both the calculator and the guide?Ĭlick here or follow the link below to download the updated Tube Section Modulus Calculator. So if you’re bending 90 degrees on a 6 CLR die, your tubing in the bend is 90.

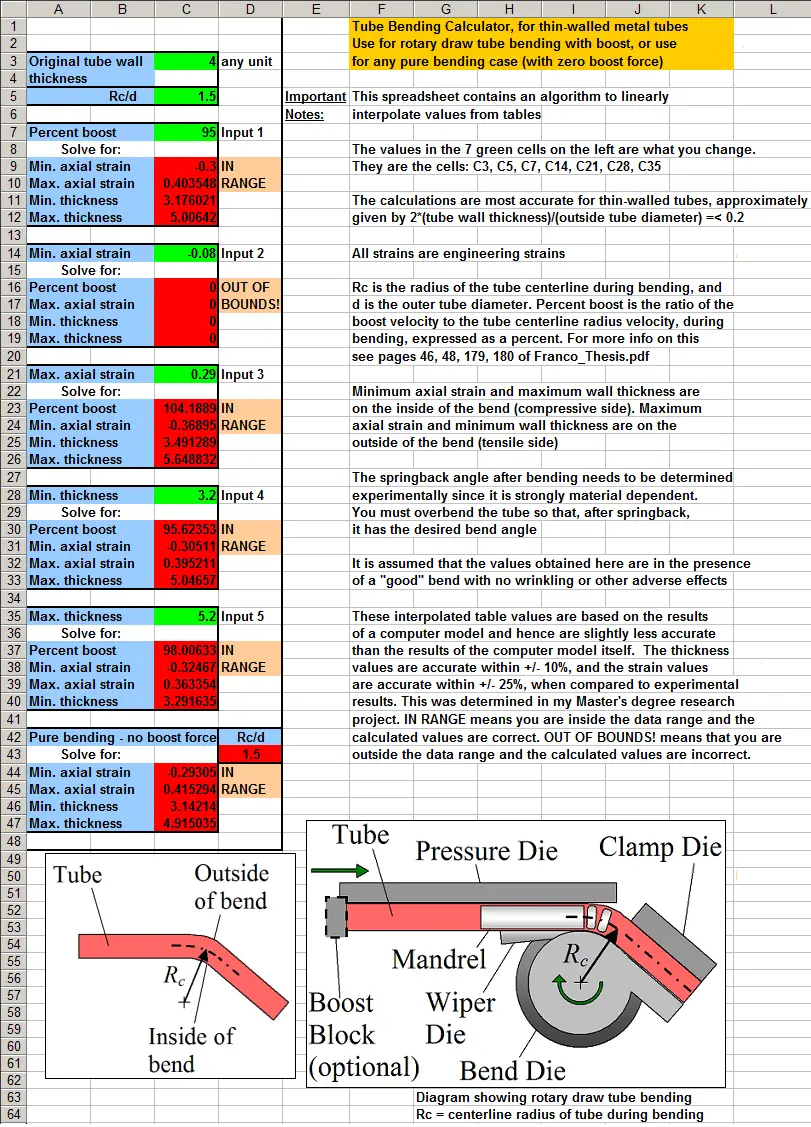

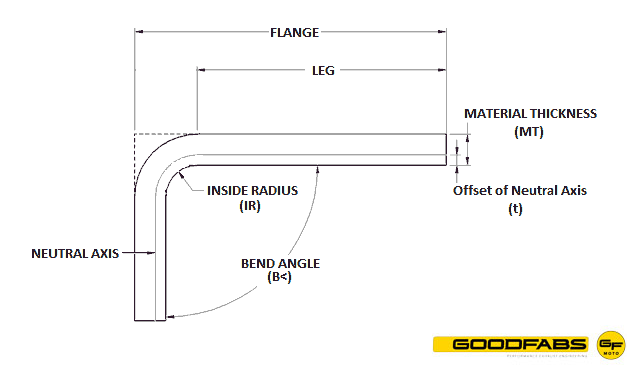

Just multiply the degrees you’re bending by the numbers below and you will get the length of tube in the bend. The Tube Bending Formulas Guide that is bundled with the calculator covers some of the most common tube bending formulas, including: Our Tube Section Modulus Calculator and Tube Bending Formulas Guide are bundled together in one download so you can have all the formulas you need in one place. Calculating the tubing in a bend is very simple. It then calculates the section area moment of inertia properties of common shapes. Some of the most common shapes covered by the calculator are: The tube bending section modulus calculator allows you to input the tube specifications into an easy to use calculator. The tube bending section modulus calculator allows you to input the tube specifications into an easy to use calculator. Our Tube Section Modulus Calculator and Tube Bending Formulas Guide are bundled together in one download so you can have all the formulas you need in one place. Whether you’re calculating the section modulus or the mandrel nose radius, evaluating whether your equipment can handle a bend, or tackling a new project having a quick formula reference can be a big help. yield stress of 30,000 psi, while Grade B pipe goes to 35,000 psi. Pipe usually doesn't have the same yield stress as things like bars, I-beams etc. Table of Factors and Terms For Bending Formulas. Please reference the Table of Factors for each of the formulas listed. And when using the wrong formulas can result in bad bends or unusable product, getting your calculations right the first time is key. bending stress will of course be reduced depending on the amount of fatigue life you wish for the piece to have. Below you will find a variety of rotary-draw tube bending related formulas and calculations to help you evaluate your tube bending application. The tube is also loosely held by two other dies, the wiper die and the pressure die. Finding the right formulas for your application alone can be frustrating. Tube bending as a process starts with loading a tube into a pipe bender and clamping it into place between two dies, the clamping block and the forming die. You can shop the Pro-Tools website for benders and dies that bend up to 2-1/2' OD if you need to bend tube or pipe larger than 2-1/2' OD, please give our expert technical sales team a call at +1 (813) 986-9000. Training Solutions for Tube Forming IndustryĬalculating the many variables needed to properly bend tube and pipe can be time consuming. The outside diameter (OD) is the distance across the extreme outside dimensions of a tube or pipe.

All Electric Left And Right Tube Benders When the ratio of the tube diameter to wall thickness is small enough, the tube can be bent on a relatively small radius (Centerline Radius or CLR 4 x Tube O.D.).

0 kommentar(er)

0 kommentar(er)